1.Mechanical properties

We introduce thelightweight, high-strength, and high-elasticity functions that are the most noticeable and used functions of CFRP. CFRP can be said to be synonymous with “light and strong” materials. Carbon composite is composite material made of carbon fiber and epoxy resin, and in addition to the following grades, it is possible to design a special product that can suit each customer’s usage.| Specific gravity |

Tensile modulus |

Tensile strength |

Flexural modulus |

Flexural strength |

Coefficient of thermal expansion |

Thermal conductivity |

||

| Class | g/㎠ | GPa | MPa | GPa | MPa | 10⁻⁶/K | W/m・K | |

| CFRP | Carbon composite ZC-60 |

1.6 | 62 | 650 | 60 | 950 | 2.5 | 2 |

| Carbon composite ZC−100 |

1.6 | 90 | 1100 | 100 | 900 | 1.7 | 2.4 | |

| Carbon composite ZC−200 |

1.7 | 180 | 200 | -0.7 | 65 | |||

| Carbon composite ZC−300 |

1.7 | 250 | 300 | -0.8 | 100 | |||

| Metal | SUS304 | 7.9 | 200 | 590 | 200 | 590 | ||

| Aluminum A5052-H34 |

2.7 | 70 | 260 | 70 | 260 | 23.8 | 137 | |

| GFRP | GFRP hand layu equivalent to JRS-FRP5 |

1.52 | 9 | 127 | 10 | 186 | ||

| Equivalent to GFRP glass epoxy laminated plate G-10 |

1.8 | 20 | 380 | 24 | 420 | 0.12 | 0.42 |

Notice:Physical properties of CFRP on this table are all performance only in the X-axis direction. In the Y-axis direction, they has a completely different property.

※The data shown is a standard value, not a guaranteed value.

| Natural frequency |

Weight | Self-weight deflection |

Load deflection |

Total | ||

| Class | Hz | kg | mm | mm | mm | |

| CFRP | Carbon composite ZC-60 | 4.9 | 2.4 | 5.0 | 2.1 | 7.1 |

| Carbon composite ZC-100 | 6.4 | 2.4 | 3.0 | 1.3 | 4.3 | |

| Carbon composite ZC-200 | 9.0 | 2.6 | 1.5 | 0.6 | 2.1 | |

| Carbon composite ZC-300 | 11.1 | 2.6 | 1.0 | 0.5 | 1.5 | |

| Metal | SUS304 | 4.0 | 12.0 | 7.6 | 0.6 | 8.2 |

| Aluminum A5052-H34 | 7.0 | 4.0 | 7.3 | 1.8 | 9.1 | |

| GFRP | GFRP hand layup equivalent to JRS-FRP5 |

2.1 | 2.3 | 28.5 | 12.5 | 41.0 |

| Equivalent to GFRP glass epoxy laminated plate G-10 |

2.9 | 2.7 | 14.0 | 5.3 | 19.3 | |

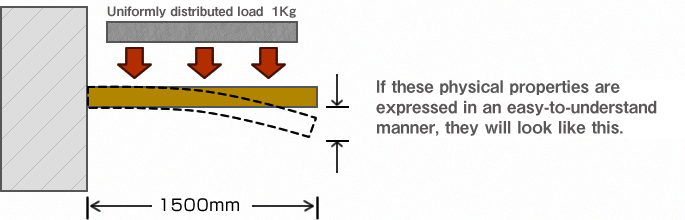

Reference: Comparison with cantilever fixed burrs of 50 mm x 1500 mm x 20 mmt

The load shall be an uniformly distributed load of 1 kg over a total length of 1500 mm.

※ The data shown is a standard value, not a guaranteed value.

2.Thermal properties

About linear thermal expansion coefficient and thermal conductivityCFRP can manufacture molding products with excellent dimensional stability due to the low coefficient of thermal expansion of carbon fiber. In addition, thermal expansion “zero” is possible depending on the design. It also has better thermal conductivity than major plastics.

| Coefficient of thermal expansion | Thermal conductivity | ||

| Class | 10⁻⁶/K | W/m・K | |

| CFRP | Carbon composite ZC-60 | 2.5 | 2 |

| Carbon composite ZC-100 | 1.7 | 2.4 | |

| Carbon composite ZC-200 | -0.7 | 65 | |

| Carbon composite ZC-300 | -0.8 | 100 | |

| Metal | SUS304 | 17.3 | 16.3 |

| Aluminum A5052-H34 | 23.8 | 137 | |

| GFRP | Equivalent to GFRP glass epoxy laminated plate G-10 | 0.12 | 0.42 |

Notice:Physical properties of CFRP on this table are all performance only in the X-axis direction. In the Y-axis direction, they has a completely different property.

※The data shown is a standard value, not a guaranteed value.

About heat resistance

We also offer heat resistant grades.

| Grade | Glass transition temperature | |

| CFRP | ZC-60~300 General grade 100℃ | 100℃ |

| ZCT-60~300 Heat resistant grade 180℃ | 180℃ | |

| ZCFT-60~300 Super heat resistant grade | 250℃ |

Notice: Heat resistance varies depending on usage conditions.

※The data shown is a standard value, not a guaranteed value.