What is CFRTP?

Fiber Reinforced Plastic is a material that adds fiber strength to the advantages of light and rust-proof plastic. In recent years, Carbon Fiber Reinforced Plastics (CFRP) using Carbon Fiber (CF) and thermosetting resin which has excellent impregnation and adhesion to the fiber, have become mainstream. CFRTP (Carbon Fiber Reinforced Thermo Plastics) is a fiber reinforced plastic that uses CF as a reinforcing material and uses thermoplastic resin as the base material instead of thermosetting resin. Since CFRP has a significantly different molding process and secondary processability from metal processing, it has been a constraint on expanding the fields of application and realizing cost-competitive FRP products. With CFRTP, the molding process can be shortened, stamping and melt bonding can be usable, and both productivity improvement and low cost can be achieved at the same time.

Fiber Reinforced Plastic is a material that adds fiber strength to the advantages of light and rust-proof plastic. In recent years, Carbon Fiber Reinforced Plastics (CFRP) using Carbon Fiber (CF) and thermosetting resin which has excellent impregnation and adhesion to the fiber, have become mainstream. CFRTP (Carbon Fiber Reinforced Thermo Plastics) is a fiber reinforced plastic that uses CF as a reinforcing material and uses thermoplastic resin as the base material instead of thermosetting resin. Since CFRP has a significantly different molding process and secondary processability from metal processing, it has been a constraint on expanding the fields of application and realizing cost-competitive FRP products. With CFRTP, the molding process can be shortened, stamping and melt bonding can be usable, and both productivity improvement and low cost can be achieved at the same time.

Features og CFRTP

CFRTP (thermoplastic resin) has the following advantages over CFRP (thermosetting resin).1. High mass productivity

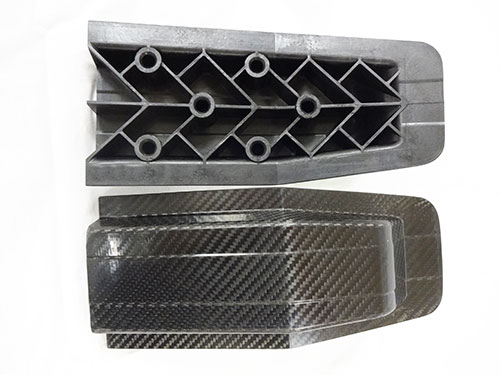

In autoclave molding which is the mainstream of CFRP molding process, the materials are laminated by hands on a mold, and then pressure / heat treatment for 8 to 12 hours is required as a curing process for thermosetting resin in the autoclave. On the other hand, CFRTP (thermoplastic resin) can reversibly repeat the solid state at room temperature and the melting state at high temperature without the need for chemical reaction. Therefore, CFRTP is a highly mass-producible material because the molding can be completed just using the time required for cooling. We can perform forming and pressurization at the same time by the press molding method of CFRTP, and can complete the cycle from material input to molding in a short period of time.

In autoclave molding which is the mainstream of CFRP molding process, the materials are laminated by hands on a mold, and then pressure / heat treatment for 8 to 12 hours is required as a curing process for thermosetting resin in the autoclave. On the other hand, CFRTP (thermoplastic resin) can reversibly repeat the solid state at room temperature and the melting state at high temperature without the need for chemical reaction. Therefore, CFRTP is a highly mass-producible material because the molding can be completed just using the time required for cooling. We can perform forming and pressurization at the same time by the press molding method of CFRTP, and can complete the cycle from material input to molding in a short period of time.

2.Various lineups of resins

There are many types of thermoplastic resins such as general-purpose (PP), engineering plastics (PA6, PA66, etc.), and super engineering plastics (PPS, PEI, PEEK, etc.). CFRTP can be selected from these resins, and can meet product requirements according to characteristics such as heat resistance, impact resistance, and chemical resistance.

3. Improvement of impact resistance and toughness

Compared to thermosetting resins, thermoplastics have higher toughness, so they have excellent impact resistance.

CFRP (thermosetting resin) can be expected to improve the interlayer strength and impact resistance, which used to be weak points.

4. Easy to storage

Thermosetting prepreg, which is a material for CFRP, requires freezing/refrigerating storage and has an expiration date.

Thermosetting prepreg, which is a material for CFRP, requires freezing/refrigerating storage and has an expiration date.

Thermoplastic prepregs can be stored at room temperature and have no expiration date, which is a great advantage in storage costs.

5. Welding is possible

CFRP parts need to be assembled with adhesive or fasteners. In addition to these assembly methods, CFRTP is capable of heat welding (melt welding) using the characteristics of thermoplastic resins.

The heat welding is expected to improve the productivity of the assembly process.

6. Recyclable

CFRP goes through a crushing process. CFRTP can be easily remelted and processed, and not only can be easily recycled into new parts by crushing (eg pelletized materials for injection molding), but also can be reused by remolding.