Benefits of using CFRP

In recent years, there have been increasing needs for high speed, high rigidity, and high precision in the field of industrial robots.

Therefore, many parts that take advantage of CFRP’s light weight, high rigidity, and static vibration are used. Although they are just a part, we will introduce some including the achievements made by us.

Therefore, many parts that take advantage of CFRP’s light weight, high rigidity, and static vibration are used. Although they are just a part, we will introduce some including the achievements made by us.

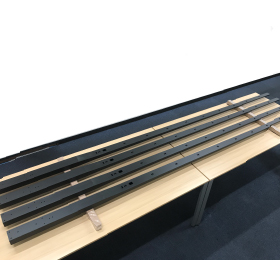

Liquid crystal glass substrate transfer arm

- Glass substrates can be transported at high speed and with high accuracy between processing devices such as film formation, resist coating, exposure, and annealing.

- The amount of deflection is reduced to prevent interference with the cassette.

- Reducing the time to converge the vibration when the hand is stopped during transfer operation.

As a result, the tact time is shortened. - We can also manufacture for 10th generation large glass substrates.

- Can be used in a high temperature environment of 250 ℃.

- Due to the low outgas specifications, the arm can be used even in a vacuum environment.

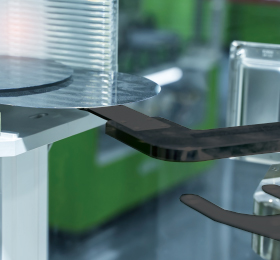

Silicon wafer transfer arm

- The amount of deflection is reduced to prevent interference with the cassette.

- Reducing the time to converge vibration when the hand is stopped during transfer operation.

As a result, the tact time is shortened. - Supporting 300 mm to 450 mm.

- Due to the low outgas specifications, the arm can be used even in a vacuum environment.

Parallel link/robot arm

- High-speed operation is possible having high rigidity.

- Since there is little overshoot or vibration, highly reliable transportation is achieved.

- Due to the excellent vibration damping property, the vibration time at the tip of the arm is suppressed and the position accuracy is improved.

- High strength and high rigidity increase the payload.

Bag making machine, film production line

- Lightweight and highly stiffness makes it possible to save labor on the motor that rotates the rollers.

- Sudden stop, high rotation, and high-speed operation can be achieved by weight reduction and low moment of inertia.

| Here for inquiries |

Inquiries by phone Settsu Factory, Osaka TEL:+81(0)72-650-2515 / FAX:+81(0)72-650-2516 Click to contact |