Thechnology of molding

Autoclave molding

In autoclave molding, prepreg is used, laminated on a mold, covered with a vacuum bag, and then the inside of the bag is evacuated and shut off from the outside air, and the pressure inside the autoclave is transmitted to the prepreg. It is molding method that has high quality reproducibility and can take advantage of the characteristics of CFRP.

In autoclave molding, prepreg is used, laminated on a mold, covered with a vacuum bag, and then the inside of the bag is evacuated and shut off from the outside air, and the pressure inside the autoclave is transmitted to the prepreg. It is molding method that has high quality reproducibility and can take advantage of the characteristics of CFRP.

Hand layup molding

A method of molding by impregnating and defoaming reinforcing fibers and resin on a mold. It is the basis of FRP molding, and it is an effective molding method for large-sized products because it is a molding method that cures at room temperature and uses atmospheric pressure to reduce initial costs such as mold costs.

A method of molding by impregnating and defoaming reinforcing fibers and resin on a mold. It is the basis of FRP molding, and it is an effective molding method for large-sized products because it is a molding method that cures at room temperature and uses atmospheric pressure to reduce initial costs such as mold costs.

Press molding

Regardless of CFRP or CFRTP, we have been developing the low cost mass production technology. In recent years, the development has been fruitful and we have started manufacturing mass-produced items, and we have received many inquiries.

Regardless of CFRP or CFRTP, we have been developing the low cost mass production technology. In recent years, the development has been fruitful and we have started manufacturing mass-produced items, and we have received many inquiries.

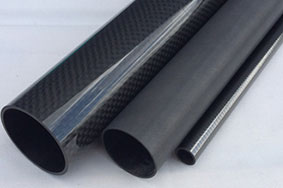

Sheet winding molding

A molding method in which prepreg is wrapped around a core (mandrel), and after that, shrink tape is wrapped around on the prepreg to cure under pressure. It is also known for molding fishing rods and golf shafts. It is suitable for pipe-shaped products and has high cost performance.

A molding method in which prepreg is wrapped around a core (mandrel), and after that, shrink tape is wrapped around on the prepreg to cure under pressure. It is also known for molding fishing rods and golf shafts. It is suitable for pipe-shaped products and has high cost performance.

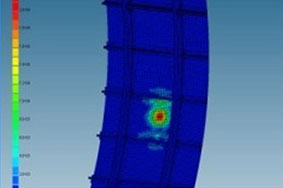

Design and Analysis

Structural design・Composite analysis・Laminate design

Composite materials can be combined with a wide variety of resins and reinforcing fibers, enabling optimal lamination design that meets the needs of our customers.

Composite materials can be combined with a wide variety of resins and reinforcing fibers, enabling optimal lamination design that meets the needs of our customers.

It is possible to propose a laminated structure suitable for composite materials.

In collaboration with Tomei Engineering, a group company, we can analyze the structure of composite materials.

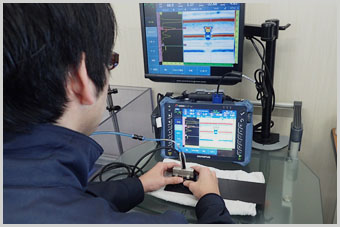

Inspection

Dimensional measurement

Dimensions and shapes can be measured using a 3D measuring device and various measuring devices.

Dimensions and shapes can be measured using a 3D measuring device and various measuring devices.

Nondestructive inspection

We have the non-destructive inspector qualification level 2 and can perform non-destructive inspection (ultrasonic flaw detection test) of composite materials.

We have the non-destructive inspector qualification level 2 and can perform non-destructive inspection (ultrasonic flaw detection test) of composite materials.